Vehicle type-approval. Legislative framework up to the year 2017.

Legislative framework up to the year 2017.

Vehicle type-approval.

1- INTRODUCTION. Considering that motor vehicles must comply with mandatory and mandatory uniform characteristics between the Member States of the European Union in order to eliminate or at least reduce the obstacles to the establishment and functioning of the common market , characteristics that starting from the year 1970 must be adopted both as a complement and in replacement of the current legislation of the member countries; whereas a check of compliance with the technical requirements has traditionally been carried out by the Member States before the vehicles to which they apply are applied and that this control covers the various types of vehicles, the EEC directive number 156 of 1970 defined the first rules of approval that the member Staes EU must adopt to allow the free movement of motor vehicles in safety. Considers vehicles for any motor vehicle designed to travel on the road, with or without a body, having at least four wheels and a maximum design speed exceeding 25 km / h, as well as its trailers, with the exception of vehicles moving on rails , tractors and agricultural machinery. In this publication (2018-19,06) research and studies are carried out in the field of legislation and vehicle type approval techniques with an interest in the evolution of the regulatory framework up to the year 2017. In the appendix the study of some analytical methods used for the construction and design of internal combustion engines with positive ignition (petrol engines) and compression ignition (diesel engines).

Under Directive 70/156, no longer in force and replaced by Directive 2007/46 / EC (Articles 1-3), it means "national type approval", the administrative act called: - agréation par type and aanneming, in the Belgian legislation, - allgemeine Betriebserlaubnis, in the German legislation, - réception par type, in the French legislation, - type approval or approval, in the Italian legislation, - agréation, in the Luxembourg legislation, - typegoedkeuring, in the legislation Dutch; "EEC type-approval" means the act by which a Member State costs a vehicle type that meets the technical requirements of the separate directives (directives which enter into force in the following period for the various elements or characteristics of the vehicle) and the checks provided for in the EEC type-approval certificate, the model of which is given in Annex II. The application for EEC type-approval is submitted by the manufacturer or his authorized representative to a Member State. It is accompanied by an information document, the model of which is set out in Annex I to Directive EEC 70/156, including the documents mentioned in the same sheet. For the same type of vehicle, this request can only be sent to one of the Member States.

In accordance with Article 4 of Directive 70/156, each Member State shall approve each type of vehicle which complies with the data set out in the information document in Annex I and which complies with the checks provided for by the type-approval certificate attached II. The Member State which has made the type-approval will take the necessary measures to monitor where conformity of production to the approved prototype is needed, if necessary in cooperation with the competent authorities of the other Member States, survey-limited surveillance. For each type of vehicle which it approves, it completes all the headings of the type-approval certificate set out above (Annex II of the EEC Directive 70/156). In accordance with Article 5, within one month, the competent authorities of each Member State shall send to those of the other Member States a copy of the information and approval forms drawn up for each type of vehicle which they approve or refuse to approve. For each vehicle constructed in accordance with the approved prototype, a certificate of conformity shall be drawn up by the manufacturer or his authorized representative in the country of registration, the model of which is set out in Annex III. The Member States may require, for the purposes of vehicle taxation or for the completion of the registration documents, that the certificate of conformity also includes indications not provided for in Annex III, provided that they appear explicitly on the information document or are deductible with calculations simple. The Member State which has granted the EEC type-approval must take the necessary measures to ensure that always be informed of the eventual suspension of production as well, of any modification of the information appearing on the information sheet. If this State considers that such a modification does not require a modification of the existing type-approval certificate or the completion of a new type-approval certificate, the competent authorities of that State shall inform the manufacturer accordingly and direct them to the competent authorities of the other Member States by grouped items and periodicals, copies of the modifications made to the information sheets already disseminated; otherwise, if a modification to the information document justifies new verifications or new tests and therefore requires a modification of the existing type-approval certificate or the compilation of a new type-approval certificate, the competent authorities of that State shall inform the manufacturer and transmit these new ones documents to the competent authorities of the other Member States, within one month from the date of their completion. In the event that an approval certificate is modified or replaced or ceases to have effect after the suspension of production of the approved type, the authorities; The competent authorities of the Member State which carried out the approval shall inform the competent authorities of the other Member States of the serial numbers of the last vehicle produced in accordance with the original datasheet and, where appropriate, the serial numbers of the first vehicle produced in accordance with the new sheet or the amended sheet.

Member States may not refuse the registration or prohibit the sale, entry into service or use of a new vehicle accompanied by a certificate of conformity on grounds relating to the construction or operation of the vehicle itself; the certificate does not prevent a Member State from adopting such measures for vehicles which do not conform to the approved prototype. Conformity with the approved prototype is considered missing when, compared to the information document, unauthorized divergences have been noted such as modifications to the vehicle which entail the modification of the homologation form not carried out and therefore not communicated to the competent authorities of the State that performed the approval and not communicated to the competent authorities of the other Member States, within one month from the date of their completion. To the extent that the separate directives provide for limit values, there is no divergence from the approved type if these limit values are observed.

When the Member State which has granted EEC component type-approval establishes that a number of vehicles, accompanied by a certificate of conformity of the same type, do not conform to the type approved by it, take the necessary measures to ensure conformity of the manufacturing with the approved type. The competent authorities of that State shall inform those of the other Member States of the measures taken, which may implement the withdrawal of the EEC type-approval. These authorities shall adopt the same provisions if they are informed by the competent authorities of another Member State of the existence of such a lack of conformity. The Directive requires the competent authorities of the Member States to inform each other within one month of the withdrawal of an EEC type-approval, including the reasons for such a measure. If the Member State which granted the EEC type-approval confirms the lack of conformity of which it has been informed, the Member States concerned will take care to settle the dispute, essentially if a vehicle produced in a Member State does not comply with the approval of the prototype of the model in another Member State, the latter has the right to obtain the adaptation of the characteristics from the Member State in which the vehicle is produced in order to comply with the approval of the prototype. The Commission is kept informed. It shall proceed, where necessary, to appropriate consultations in order to reach a solution.

A dynamic that has spread in many other industrial sectors in the last decades, even if regulated in a different way as the production of goods with an international brand respecting the quality standards imposed by the owner of the brand (technical specifications, design specifications ); in the case of vehicles above quality, safe circulation is of primary importance.

The Directive EEC 70/156 with the rule of Article 9 states that if a Member State costs that vehicles belonging to the same type, even if accompanied by a certificate of conformity duly issued, compromise the safety of road traffic, it may, for a maximum period of six months, refuse to register or prohibit the sale, putting into circulation or use on its territory. The Member State in question shall immediately inform the other Member States and the Commission, stating the reasons for its decision. The EEC directive 70/156 is implemented in Italy with the Ministerial Decree for Transport and Civil Aviation (Today, Ministry of Transport and Infrastructures of 29 March 1974 and published in the Official Gazette number 105 of 23 April 1974.

The Council of the European Community adopts Directive 77/143 / EEC with provisions on periodic checks that Member States must implement in order to ensure greater safety for the movement of motor vehicles of certain categories (periodic review). Subsequently, it proceeds to recast Directive 77/143 / EEC through Directive 96/96 / EEC, which in turn was repealed by Directive 2009/40 / EC finally repealed by Directive 2014/45 / EC which establishes a periodic inspection (revision) of motor vehicles of category M1 equal to 4 years from the date of matriculation and subsequently every 2 years. With Directive 2014/45 / EC, the Parliament and the European Commission establishes the minimum requirements concerning the object and methodology of a recommended control, the minimum content of a certificate of revision, the minimum requirements for installations and control equipment , the minimum requirements related to the competence, training and certification of the inspectors, the minimum requirements of the institutions supervising institutions by the Member States. Directive 77/143 / EEC enters into force on the twentieth day following its publication in the Official Journal of the European Union for Member States. The Italian Republic adopts the directive 2014/45 / CE with Ministerial decree of 19 May 2017 adopted by the Ministry of Infrastructures and Transport.

2 - LEGISLATIVE UPDATE FOR TYPE-APPROVAL OF MOTOR VEHICLES AND THEIR TRAILERS.Considering that Council Directive 70/156 / EEC of 6 February 1970 on the approximation of the laws of the Member States relating to the type-approval of vehicles motor vehicles and their trailers, has undergone several and substantial modifications, on the occasion of new modifications it is appropriate, for reasons of clarity, to proceed with its recasting, then to the grouping and integration of the previous regulations in force concerning the type-approval of motor vehicles and their trailers, as well as the systems, components and separate technical units intended for such vehicles, through the adoption of Directive 2007/46 / EC. For the purposes of the establishment and functioning of the internal market of a (European) Community, when technological reasons and measures aimed at increasing safety for vehicle drivers, for people around them and the environment, make it necessary to modify the framework for the approval of motor vehicles and their trailers, and of the systems, components and separate technical units intended for such vehicles, it is appropriate to replace the systems of approval by the Member States by an appropriate Community procedure based on the principle of total harmonization.

The European Parliament and the Commission of the European Union considers that the technical requirements applicable to systems, components, separate technical units and vehicles should be harmonized and specified in legislative acts. Such regulatory acts should primarily aim to ensure a high level of road safety, health protection, environmental protection, energy efficiency and protection against unauthorized use. Considering that the producers of small vehicles in small series have been partially excluded from the benefits of the internal market, and that experience has shown significant improvements in safety if vehicles produced in small series were fully integrated into the Community vehicle type-approval system, starting with those in the M1 category, to avoid abuse, a simplified procedure for small-scale vehicles should be applied only in cases where production is very limited, it is therefore necessary to define more precisely the concept of small series in terms of the number of vehicles produced. These limits are set out in Section A of Annex XII of Directive 2007/46 / EC: for example for M1 (1°) category lanes not exceeding 1000 units to be put into circulation or sold in the European Union or not more than 75 units in the Member State.

(1°) NOTE: Some information in Annex II, Part A, paragraph 1 of Directive 2007/46 / EC. Vehicle categories: for the purposes of European and national type-approval as well as for individual type-approval vehicles must be classified according to the following classification: Category M: motor vehicles designed and constructed essentially for the transport of persons and their luggage.Category M1: vehicles of category M, having a maximum of eight seats in addition to the driver's seat. There is no room for standing passengers in vehicles of category M1. The number of seats can be limited to one (ie the driver's seat). Category M2: vehicles of category M, having more than eight seats in addition to the driver's seat and with a maximum mass not exceeding 5 tonnes. Vehicles in category M2 may have space for standing passengers in addition to seats. Category M3: vehicles of category M, having more than eight seats in addition to the driver's seat and with a maximum mass exceeding 5 tonnes. Vehicles in category M3 may have space for standing passengers. Category N: motor vehicles designed and constructed primarily for the transport of goods. Category N1: vehicles of category N with a maximum mass not exceeding 3.5 tonnes. Category N2: vehicles of category N with a maximum mass of between 3.5 and 12 tonnes. Category N3: vehicles of category N with a maximum mass exceeding 12 tonnes. Category O: trailers designed and built for the transport of goods or people as well as for housing people. Category O1: vehicles of category O with a maximum mass not exceeding 0,75 tonnes. Category O2: vehicles of category O with a maximum mass exceeding 0.75 tonnes and less than 3.5 tonnes. Category O3: vehicles of category O with a maximum mass exceeding 3.5 tonnes and less than 10 tonnes. Category O4: vehicles of category O with a maximum mass exceeding 10 tons.

It is important to have measures that allow the approval of vehicles on an individual basis, in particular to introduce some flexibility in the multi-stage type-approval system. However, pending the entry into force of specific harmonized standards at Community level, Member States should be able to continue to issue individual approvals in accordance with their national rules. (Chapter X of Directive 2007/46 / EC).

By Council Decision 97/836 / EC, the Community has acceded to the United Nations Economic Commission for Europe Agreement on the adoption of uniform technical prescriptions applicable to motor vehicles, accessories and parts which may be installed and / or used on motor vehicles and the conditions for mutual recognition of approvals issued on the basis of these requirements ("revised 1958 agreement") (2°).

(2°) NOTE: Agreement of 20 March 1958 on the adoption of UN harmonized technical regulations for wheeled vehicles, equipment and parts that they can be installed or used in wheeled vehicles, as well as the conditions for the mutual recognition of approvals granted on the basis of these UN regulations.

The Regulations of the United Nations Economic Commission for Europe (UNECE) to which the Community accedes pursuant to that Decision and the amendments to the UNECE Regulations to which it has already acceded should be incorporated into the Community approval procedure as requirements relating to EC type-approval of vehicles or as alternatives to existing Community legislation. In particular, where the Community, by means of a Council Decision, decides that a UNECE Regulation should be integrated into the EC vehicle type-approval procedure and replaces the existing Community legislation, the Commission has the power to make the necessary adjustments to this Directive. These general measures designed to amend non-essential elements of Directive 77/143 / EEC (the subject of studies in the previous paragraph, periodic review of motor vehicles circulating on the road) or supplement it by adding new non-essential elements, should be adopted in accordance with the regulatory procedure with scrutiny referred to in Article 5a of Decision 1999/468 / EC. (Chapter XIII). Directive 46/2007 / EC, which is being studied in this paragraph, and subsequent amendments establishes that manufacturers must be subjected to regular checks by the competent authorities or by a designated technical service with the necessary qualifications.

Directive 46/2007/ EC constitutes a series of safety requirements in accordance with Article 1 (2) of Directive 2001/95 / EC of the European Parliament and of the Council of 3 December 2001 on general product safety, laying down specific requirements to protect the health and safety of consumers. It is therefore important to lay down provisions to ensure that, in the event that a vehicle presents a serious risk to consumers, resulting from the application of the same directive or regulatory acts listed in Annex IV, the manufacturer has taken effective protective measures, including the recall of vehicles. The approval authorities should therefore be able to assess whether or not the proposed measures are sufficient; logic that defines Article 32 of the same Directive 46/2007 / EC. Finally, the European Parliament and the Commission of the European Union deem it important for manufacturers to provide vehicle owners with the information necessary to avoid the misuse of safety devices. It is therefore appropriate to include provisions in this directive 46/2007/EC. It is equally important that equipment manufacturers have access to certain information, which is only available from the vehicle manufacturer, ie the technical information, including drawings, necessary to produce the parts intended for the after-sales assistance market. IS equally important that manufacturers make information easily accessible to independent operators, in order to ensure the repair and maintenance of vehicles in a fully competitive market. (Chapter XIV of Directive 2007/46 / EC).

The following are the directives and the regulations that modify the EC directive 2007/46 (the attachments):

Regulation (CE) n. 1060/2008 of the Commission of 7 October 2008 (which replaces Annexes I, III, IV, VI, VII, XI and XV of Directive 2007/46 / EC)

Regulation (EC) n. 78/2009 of the European Parliament and of the Council of 14 January 2009 (concerning the approval of motor vehicles in relation to the protection of pedestrians and other vulnerable road users, amending Directive 2007/46 / EC and repealing the 2003 directives / 102 / CE and 2005/66 / CE)

Regulation (EC) n. 79/2009 of the European Parliament and of the Council of 14 January 2009 (relating to the type-approval of hydrogen powered motor vehicles and amending Directive 2007/46 / EC)

Regulation (EC) no. 385/2009 of the Commission of 7 May 2009 (replacing the Annex IX of the Directive 2007/46 / CE)

Regulation (CE) n. 595/2009 of the European Parliament and of the Council of 18 June 2009 (on the approval of motor vehicles and engines with regard to emissions from heavy vehicles (euro VI) and access to vehicle repair and maintenance information, and amending Regulation (EC) No 715/2007 and Directive 2007/46 / EC and repealing Directives 80/1269 / EEC, 2005/55 / EC and 2005/78 / EC)

Regulation (EC) n. 661/2009 of the European Parliament and of the Council of 13 July 2009 (on the type-approval requirements for the general safety of motor vehicles, their trailers and systems, components and facilities designed for them, amend Annexes IV, VI, XI and XV of Directive 2007/46 / EC)

Commission Directive 2010/19 / EU of 9 March 2010 as amended by Commission Decision 2011/415 / EU of 14 July 2011 (amending, for the purpose of adaptation to technical progress in the spray-suppression system of certain categories of motor vehicles and their trailers, Council Directive 91/226 / EEC and Directive 2007/46 / EC of the European Parliament and of the Council)

Regulation (EU) n. 371/2010 of the Commission of 16 April 2010 (replacing Annexes V, X, XV and XVI of Directive 2007/46 / EC)

Regulation (EU) n. 183/2011 of the Commission of 22 February 2011 (amending Annexes IV and VI of Directive 2007/46 / EC)

Regulation (EU) n. 582/2011 of the Commission of 25 May 2011 (implementing and amending Regulation (EC) No 595/2009 of the European Parliament and of the Council with regard to emissions from heavy vehicles (Euro VI) and amending Annexes I and III of Directive 2007/46 / EC of the European Parliament and of the Council)

Regulation (EU) n. 678/2011 of the Commission of 14 July 2011 (replacing Annex II and modifying Annexes IV, IX and XI of Directive 2007/46 / EC)

Regulation (EU) n. 65/2012 of the Commission of 24 January 2012 (implementing Regulation (EC) No 661/2009 of the European Parliament and of the Council on gear shift indicators and amending Directive 2007/46 / EC of the European Parliament and of the Council )

Regulation (EU) n. 1229/2012 of the Commission dated 10 December 2012 (amending Annexes IV and XII of Directive 2007/46 / EC)

Regulation (EU) n. 1230/2012 of the Commission of 12 December 2012 (implementing Regulation (EC) No 661/2009 of the European Parliament and of the Council as regards the type approval requirements for the masses and dimensions of motor vehicles and their trailers and amending Directive 2007/46 / EC of the European Parliament and of the Council)

Regulation (EU) n. 143/2013 of the Commission of 19 February 2013 (amending Directive 2007/46 / EC of the European Parliament and of the Council and Commission Regulation (EC) No 692/2008 as regards the determination of CO2 of the vehicles undergoing approval in more phases)

Regulation (EU) no. 171/2013 of the Commission of 26 February 2013 (amending Annexes I and IX, replaces Annex VIII of Directive 2007/46 / EC of the European Parliament and of the Council establishing a framework for the approval of motor vehicles and their trailers, as well as the systems, components and other techniques for such vehicles (framework directive) and amending Annexes I and XII of Commission Regulation (EC) No 692/2008 implementing and amending Regulation (EC) No 715/2007 of the European Parliament and of the Council concerning the approval of motor vehicles with respect to emissions from light commercial and passenger vehicles (Eur 5 and Eur 6) and to obtaining information for the repair and maintenance of the vehicle)

Regulation (EU) n. 195/2013 of the Commission of 7 March 2013 (amending Directive 2007/46 / EC of the European Parliament and of the Council and Commission Regulation (EC) No 692/2008 as regards innovative technologies aimed at reducing emissions of CO 2 from passenger and light commercial vehicles)

Council Directive 2013/15 / EU of 13 May 2013 (adapting certain directives on the free movement of goods by reason of the Accession of the Republic of Croatia).

Of interest for this research, with reference to the legislative framework that defines a regulatory system for the approval of the vehicle series (the prototype) in safety and with particular reference to Directive 2007/46 / EC in this paragraph: in order to harmonize the legislative framework for the approval of vehicles in circulation in the Community the European Directive applies to the homologation of vehicles designed and manufactured in one or more phases in order to be used on the road, as well as of systems, components and entities techniques designed and manufactured for the aforementioned vehicles. It also applies to the individual type approval of these vehicles. The same directive also applies to parts and equipment intended for vehicles contemplated by it. The Directive does not apply to the type-approval or individual type-approval of the following vehicles: agricultural or forestry tractors as defined in Directive 2003/37 / EC of the European Parliament and of the Council of 26 May 2003 (replaced by EU Regulation 167 / 2013), concerning the approval of agricultural or forestry tractors, their trailers and their interchangeable towed machines, as well as of systems, components and entities techniques of such vehicles, and trailers designed and manufactured specifically to be towed by them; quadricycles as defined in Directive 2002/24 / EC of the European Parliament and of the Council of 18 March 2002 (replaced by EU regulation 168/2013) concerning the approval of two- or three-wheel motor vehicles; tracked vehicles. The approval or individual approval, governed by Directive 2007/46 / EC, is optional for the following vehicles: vehicles designed and manufactured to be essentially used on construction sites, quarries, port or airport installations; armored vehicles designed and manufactured for use by the armed forces, civil protection, fire services and services responsible for maintaining public order; mobile machinery, to the extent that these vehicles meet the requirements of the Directive. These optional approvals do not prejudice the application of Directive 2006/42 / EC of the European Parliament and of the Council of 17 May 2006 on machinery (to be studied in forthcoming publications). The individual approval according to the directive is optional for the following vehicles: vehicles intended exclusively for road racing; prototypes of vehicles used on the road under the responsibility of a manufacturer for carrying out specific test programs provided have been designed and manufactured specifically for this purpose.

The procedures for the EC type-approval of vehicles are divided into stages approval, homologation in a single stage; mixed approval. The manufacturer shall submit the application to the approval authority. For a particular type of vehicle, only one application can be submitted and in one Member State. Furthermore, the application for approval for one type of system, component or separate technical unit can be submitted only one application and in one Member State only. For each type to be approved, a separate application is presented. The application is accompanied by an informative documentation, the content of which is specified in the separate directives or regulations. Upon the duly motivated request of the approval authority, the manufacturer may be requested to provide further information necessary for the purpose of deciding on the proof required or to facilitate the performance of the tests. The manufacturer shall make available to the approval authority the quantity of vehicles, components or separate technical units required by the relevant special directives or regulations for the purpose of carrying out the required tests.

Tests required for EC type-approval: 1) compliance with the technical requirements contained in the Directive Directive 2007/46 / EC and in the regulatory acts listed in the relevant Annex IV shall be demonstrated by appropriate tests performed by designated technical services. The test procedures, equipment and specific tools necessary for carrying out the tests are described in each of the regulatory acts. 2) The necessary tests are performed on vehicles, components and technical units representative of the type to be approved. At the request of the manufacturer, as an alternative to the test procedures and with the approval of the approval authority, virtual test methods may be used for the regulatory acts listed below including the general conditions that the virtual test methods must satisfy.

List of regulatory acts for virtual tests. Directive 70/221 / EEC: fuel tanks / rear protective devices. Directive 70/387 / EEC: door locks and hinges. Directive 2003/97 / EC: devices for indirect vision. Directive 74/60 / EEC: interior finishes 16. Directive 74/483 / EEC: external projections. Directive 76/756 / EEC: installation of lighting and light-signaling devices. Directive 77/389 / EEC: towing devices. Directive 77/649 / EEC: field of visibility & agrave; front 35. Directive 78/318 / EEC Windscreen wipers / wipers 37. Directive 78/549 / EEC Wheel mudguards. Directive 89/297 / EEC: side protection. Regulation (EU) n. 1230/2012: Directive 92/114 / EEC: external projections of the cabins. Directive 94/20 / EC: coupling devices. Directive 2001/85 / EC: buses. Directive 2000/40 / EC: front underrun protection.

The following diagram is used as a basic structure for the description and execution of virtual tests: a) purpose; b) structure model; c) limit conditions; d) load hypothesis; e) calculation; f) evaluation; g) documentation. The fundamental data of calculation and computer simulation are: mathematical model provided by the manufacturer. It reflects the complexity of the vehicle structure, the system and the components to be tested in relation to the requirements of the regulatory act and its limit conditions. The same provisions shall apply mutatis mutandis to the tests of the components or technical entities irrespective of the vehicle. Process of validation of the mathematical model: the mathematical model is validated according to the actual test conditions. To this end, a physical test is carried out in order to compare the results with those obtained with the mathematical model. The comparability of the test results is then demonstrated. The manufacturer or the technical service shall draw up a validation report and submit it to the approval authority. Any changes made to the mathematical model or software likely to invalidate this report must be communicated to the type approval authority that may request a new validation. The diagram of the validation process is shown in the figure.

Documentation: The manufacturer provides the data and auxiliary tools used for simulation and calculation, duly documented. At the request of the technical service, the manufacturer provides or makes accessible the necessary tools, including the appropriate software. It also provides appropriate assistance to the technical service. The access and assistance offered to the technical service does not exempt the latter from fulfilling its obligations regarding staff skills, payment of license fees and respect for confidentiality.

For the individual regulatory acts listed above (Annex XVI of Directive 2007/46 / EC) the specific test conditions and the corresponding administrative provisions are set out in Appendix 2 of the same annex. The Commission shall establish the list of regulatory acts for which virtual testing methods, specific conditions and corresponding administrative provisions are authorized. These measures, designed to amend non-essential elements of the Directive, including by supplementing it, shall be established and updated in accordance with the regulatory procedure with scrutiny defined in Article 5, paragraphs 1 to 4, and Article 7 of Decision 1999/468 / EC, taking into account the provisions of Article 8 thereof. The Member State issuing EC type-approval shall take the necessary measures pursuant to Annex X (Directive 2007/46 / EC) to verify, if necessary in cooperation with the authorities; approval of other Member States, if appropriate measures have been taken (and if such measures are appropriate in the period following approval for production) to ensure conformity; to the approved type of vehicles, systems, components or entities; technical products. The verification carried out to ensure compliance to the approved type is limited to the procedures set out in Annex X and in regulatory acts containing specific requirements. To this end the competent authority is competent of the Member State which issued the EC type-approval carry out any checks or tests required by the regulatory acts listed in Annex IV or in Annex XI (Directive 2007/46 / EC) on samples taken at the manufacturer's premises, including production facilities. Where a Member State which has granted an EC type-approval finds that the above provisions have not been applied, they diverge significantly from the measures and control plans agreed or ceased to be applied although production has not been interrupted, it adopts the necessary measures, including withdrawal of type approval, to ensure that the compliance procedure is correctly followed; of production.

The manufacturer is obliged to immediately inform the Member State which granted the EC type approval of any modification of the information in the information package. This Member State decides the procedure to be followed in accordance with the provisions of Chapter V of Directive 2007/46 / EC. If necessary, the Member State may decide, in consultation with the manufacturer, that a new EC type-approval is to be issued. The application for amendment of an EC type-approval shall be submitted exclusively to the Member State which granted the original EC type-approval, and if it considers that new inspections or new tests are required to introduce an amendment, it shall inform the manufacturer. The following procedures apply only after the successful outcome of the new inspections or the new tests required: the modification of the indications included in the type-approval file is known as the revision. In this case, the approval authority shall issue, if necessary, the modified page or pages of the information package, indicating clearly on each modified page the nature of the modification and the date of the new issue. A unified and updated version of the type-approval file, accompanied by a detailed description of the changes, is considered to comply with this requirement. The revision is called an extension if, in addition to the updating of the type-approval package, further inspections or new tests are required, or one of the information on the EC type-approval certificate, excluding the annexes, has been amended, or new requirements under one of the regulatory provisions applicable to the approved vehicle come into force (in this latest trend there is no need to change the type approval of a vehicle type if the new requirements are technically irrelevant for that type of vehicle or concern other categories of vehicles). In such cases, the approval authority issues a revised EC type-approval certificate, marked with a progressive extension number according to the number of subsequent extensions already issued. The approval form clearly shows the reason for the extension and the date of the new issue. Whenever modified pages or a unified and updated version are released, the index of the approval file attached to the type approval form shall be amended accordingly, indicating the date of the most recent extension or revision or the latest version unification updated.

In the case of an extension, the approval authority shall update all relevant sections of the EC type-approval certificate, its annexes and the index of the type-approval file. The updated form and related annexes are issued to the applicant without undue delay; the approval authority shall issue to the applicant without undue delay, as appropriate, the revised documents or the unified and updated version, including the revised index of the information package; in addition, it shall inform the homologous authorities of the other Member States of all modifications to the EC type-approvals in accordance with the procedures referred to in Article.

The EC type-approval of a vehicle ceases to be valid in the following cases: (a) when new requirements covered by a regulatory act applicable to the approved vehicle become mandatory for the registration, sale or entry into service of new vehicles and not possible update the approval accordingly; (b) when the production of the approved vehicle ceases definitively by voluntary initiative; (c) when the validity of the type-approval ceases as a result of a special restriction. When the termination of validity concerns only a variant of a type or version of a variant, the EC type-approval of the vehicle in question loses its validity in respect of the particular variant or version concerned. When the production of a vehicle type ceases definitively, the manufacturer shall inform the authority which issued the EC type-approval for the vehicle. Upon receipt of the notification, that authority shall inform the other Member States of the homologous authorities within twenty working days. If the production of the vehicle takes place as a result of new requirements covered by a regulatory act applicable to the approved vehicle, Member States may authorize the registration and sale (or putting into circulation) of vehicles conforming to the prototype the EC component type-approval of which is not most valid, article 27 of Directive 2007/46 / EC (3°). Without prejudice to paragraph 3 (definition used in the Directive and in the regulatory acts referred to in Annex IV,requirements for the EC type-approval of vehicles), when an EC type-approval of a vehicle loses its validity, the manufacturer shall inform the authority which granted the EC type-approval. It shall communicate without undue delay to the equivalent authorities of the other Member States all relevant information to allow for the possible application of Article 27 (3°). This communication specifies in particular the production date and the identification number of the last vehicle produced.

(3°) NOTE: Article 27 of Directive 2007/46 / EC. Limits set out in Annex XII, Section B: the maximum number of complete vehicles according to the end of series procedure is limited according to one of the following methods, chosen by the Member State: 1) the maximum number of vehicles of one or more types can not, for category M 1, can not exceed 10% and, for vehicles of all other categories, 30% of the vehicles of all types concerned put into circulation in the same State member during the previous year. If the values corresponding to 10% or 30% are less than 100 vehicles, the Member State may authorize the putting into circulation of a maximum number of 100 vehicles; 2) the number of vehicles of a given type is limited to those bearing a valid certificate of conformity issued on or after the production date which has remained valid for a period of at least three months after the date of issue, but has lost validity following the entry into force of a regulatory act. Within the above limits and only for a limited period, Member States may register and authorize the sale or entry into service of vehicles conforming to a type of vehicle whose EC type-approval is no longer valid. The logic of the previous rule is applicable only to vehicles in the territory of the Community subject to EC type-approval valid at the time of their production but not registered or put into circulation before this EC type-approval becomes invalid. The possibility of registering vehicles at the end of the series is limited, for complete vehicles, to a period of twelve months from the date of expiry of the validity of the EC type-approval and, for completed vehicles, to a period of eighteen months from that date. A manufacturer wishing to make use of the "end-of-series" provisions shall submit a request to the competent authority of each Member State concerned to put the vehicles in question on the road. This request must specify the technical or economic reasons which prevent the vehicles from complying with the new technical requirements. Within three months of receiving this request, the Member States concerned shall decide whether, and in what number, to authorize the registration of such vehicles within their territory. Paragraphs 1, 2 and 3 shall apply mutatis mutandis to vehicles which are the subject of a national type-approval but which have not been registered or put into circulation before the validity of that approval ceases, in accordance with Article 45 (Article 45 of Directive 2007/46 / EC establishes the dates of application for EC type-approval), due to the obligation to apply the EC type-approval procedure. Member States shall apply appropriate measures to ensure that the number of vehicles to be registered or put into circulation under the same standard procedure is effectively monitored.

Application dates for EC type-approval. With regard to EC type-approval, Member States shall grant EC type-approvals to new types of vehicles as from the dates set out in Annex XIX to Directive 2007/46 / EC. At the request of the manufacturer, Member States may issue EC type approvals for new types of vehicles from 29 April 2009. Until the dates specified in the fourth column of the table in Annex XIX, the manufacturer holding an EC type-approval certificate a vehicle is not obliged to issue a certificate of conformity accompanying each complete vehicle, incomplete or completed, manufactured in accordance with the approved vehicle type, with reference to new vehicles for which a national type-approval has been issued before the dates specified in the third column or for which a type approval has not been issued. At the request of the manufacturer and within the dates specified in the third column of rows 6 and 9 of the table in Annex XIX, Member States shall continue to issue national approvals, as an alternative to EC vehicle type-approval, for vehicles of category M< sub>2 or M3 provided that these vehicles and their systems, components and individual technical units have been approved in accordance with the regulatory acts listed in Annex IV, Part I, of Directive 2007 / 46 / EC. 5. The EC type-approvals granted to vehicles of category M1 before 29 April 2009 shall not be invalid, the extension of such approvals shall not be impeded. As regards the EC type-approval of new types of systems, components or separate technical units, Member States shall apply Directive 2007/46 / EC as from 29 April 2009. EC type-approvals issued to systems, components or separate technical units shall not be invalidated before 29 April 2009, the extension of such approvals is not hindered.

The manufacturer holding an EC vehicle type-approval certificate shall issue a certificate of conformity accompanying each complete, incomplete or completed vehicle manufactured in accordance with the approved vehicle type. If it is an incomplete or completed vehicle, the manufacturer shall indicate on page 2 of the certificate of conformity only the elements added or modified during the phase of approval and, if necessary, attach to the certificate all the certificates of conformity issued during the course of the previous phase. The certificate of conformity is drawn up in one of the official languages of the Community. Each Member State may request that the certificate of conformity be translated into its own language or languages. The certificate of conformity is designed in such a way that it can not be falsified. To this end, the card used is protected by a color graphic or by the manufacturer's identification mark affixed in watermark; it is completed in its entirety and contains no restrictions on the use of the vehicle that are not required by a regulatory act. The certificate of conformity referred to in Annex IX, Part I, of vehicles approved with provisional approval and valid only in the territory of the issuing Member State, bears the indication in the header For completed / completed vehicles approved in accordance with Article 20 (provisional approval). The certificate of conformity referred to in Part I of Annex IX for vehicles with EC type-approval for small series of production bears the heading For complete / completed vehicles type-approved in small series and in proximity year of production followed by a sequential number from 1 up to the limit indicated in the table in Annex XII, which for each year of production identifies the position of the vehicle in the production authorized for that year. The manufacturer may transmit electronically data or information contained in the certificate of conformity to the entity responsible for the registration of the Member State and only the manufacturer may issue a duplicate of the certificate of conformity. The term duplicate must be clearly visible on the front of each duplicate certificate.

If a Member State finds that new vehicles, systems, components or entities techniques, even if they comply with the relevant requirements or duly marked with a trade mark, present a serious risk to road safety or seriously harm the environment or public health; refuse, for a maximum period of six months, to register such vehicles or to authorize the sale or putting into circulation on their territory of such vehicles, components or entities; techniques. In such cases, the Member State concerned shall immediately inform the manufacturer, the other Member States and the Commission, stating the reasons for its decision and indicating, in particular, determined by: shortcomings in the relevant regulatory acts, or incorrect application of the relevant provisions. The Commission consults at the most soon the interested parties, in particular the authority which issued the approval, in order to prepare the decision. Where measures are determined by deficiencies in the relevant regulatory acts, appropriate measures shall be taken as follows: in the case of special directives or regulations listed in Part I of Annex IV, the Commission shall amend them in accordance with the regulatory procedure with scrutiny of referred to in paragraphs 1 to 4, and Article 7 of Decision 1999/468 / EC, having regard to the provisions of Article 8 thereof; in the case of UNECE regulations, the Commission proposes the necessary draft amendments to the UNECE regulations in question according to the applicable procedure under the revised 1958 Agreement. Where the measures are due to incorrect application of the relevant requirements, the Commission shall take appropriate measures to ensure compliance; to these requirements.

A manufacturer who has obtained the EC type-approval of a vehicle and who, pursuant to a regulatory act or Directive 2001/95 / EC (on general product safety), is obliged to make a recall of vehicles already sold, registered or put in circulation because one or more systems, components or separate technical units fitted to the vehicle, whether or not they are duly approved in accordance with Directive 2007/46 / EC, present a serious risk to road safety, public health or environment, immediately inform the authority that issued the vehicle type approval. The manufacturer shall propose the appropriate remedies to the approval authority to neutralize the risk indicated above. The approval authority shall immediately communicate the proposed measures to the authorities of the other Member States. The competent authorities shall ensure the effective application of the measures in their respective territories. If the measures are not considered sufficient by the authorities concerned, or have not been applied promptly, they shall inform the authority which granted the EC type-approval of the vehicle without delay. The approval authority then informs the manufacturer. Where the authority which granted the EC type-approval is not satisfied with the manufacturer's measures, it shall take all necessary precautionary measures, including the withdrawal of the EC vehicle type-approval if the manufacturer does not propose and does not implement effective remedies. In the event of withdrawal of the EC vehicle type-approval, the approval authority concerned shall inform the manufacturer, the competent authorities of the other Member States and the Commission by registered letter or equivalent electronic means within twenty working days. This standard of Directive 2007/46 / EC also applies to parts that are not subject to any requirement by virtue of a regulatory act. Any decision taken in accordance with the provisions adopted in implementation of this Directive and any decision to refuse or withdraw an EC type-approval, refusal of registration or prohibition of sale shall be duly justified. These decisions shall be notified to the interested party together with an indication of the legal remedies provided for by the legislation in force in the Member States concerned and the related time limits.

Directive 70/156 / EEC is repealed with effect from 29 April 2009 without prejudice to the obligations of the Member States relating to the time limits for transposition into national law and application of the directives indicated in Annex XX, Part B to Directive 2007/46 / EC . References to the repealed Directive contained in Directive 2007/46 / EC shall be construed as references to the Directive and be read in accordance with the correlation table set out in Annex XXI thereto. Directive 2007/46 / EC of the European Parliament and of the Council of 5 September 2007 relating to the type-approval of motor vehicles and their trailers, and of the systems, components and technical units intended for such vehicles, is implemented in Italy with the Decree Law of 28 April 2008 adopted by the Ministry of Transport and Infrastructure. It is published in the Ordinary Supplement n. 167 to the Official Gazette n. 162 of 12 July 2008.

3 - GENERAL REQUIREMENTS AND TESTS FOR SAFETY CIRCULATION OF MOTOR VEHICLES AND.With Regulation 661/2009 / EC, the European Parliament and the Council of the European Union have defined a set of safeguarding the safety in the circulation of motor vehicles including: electronic stability control: an electronic control function of a vehicle that improves its dynamic stability; lane deviation warning system: a system that warns the driver of an involuntary drift of the vehicle from its lane; advanced emergency braking device: a device capable of automatically identifying an emergency situation and activating the vehicle's braking system to slow it down in order to avoid or mitigate a collision; load capacity index: one or two numbers that indicate the load that the tire can bear, individually or in single and coupled configuration, at the speed corresponding to the associated speed category and if used in accordance with the requirements specified by the manufacturer; tire pressure monitoring system: a vehicle-mounted system capable of assessing tire pressure or pressure changes over time and transmitting related information to the user while the vehicle is being driven ; unprotected road user: pedestrians, cyclists and motorcyclists; gear shift indicator or GSI: a visible device that advises the driver to change gears; manual transmission: a gearbox that can be used in a mode in which the change between all or some of the gears is always derived directly from a driver's action, regardless of how it was physically implemented; this definition does not include systems where the driver can only choose a certain gear shifting strategy a priori or limit the number of gears available while driving, but where the actual gear shift is autonomously initiated by the driver's decision, based on certain driving methods. Regulation 661/2009 / EC establishes the requirements for the approval of motor vehicles and their trailers as well as of the systems, components and separate technical units intended for their safety; lays down the requirements for the approval of motor vehicles, with reference to tire pressure monitoring systems, with regard to their safety, fuel efficiency and CO2 emissions; and, with regard to gear shift indicators, with reference fuel efficiency and emissions CO2 emissions and for the approval of newly manufactured tires with regard to their safety and performance performance rolling resistance and rolling noise.

Manufacturers shall ensure that vehicles are designed, constructed and assembled in such a way as to minimize the risk of injury to vehicle occupants and other road users. They also ensure that vehicles, systems, components and separate technical units meet the relevant requirements set by Regulation 661/2009 / EC and its implementing measures (detailed rules on procedures, tests and specific technical requirements for type-approval motor vehicles, their trailers, components and separate technical units), including the requirements relating to: (a) the integrity of the vehicle structure, including the impact tests; (b) systems that assist the driver in controlling the vehicle, including steering, brakes and electronic stability control systems; (c) systems designed to inform the driver, acoustically or visually, of the condition of the vehicle and of the surrounding area and including glazing, mirrors and driver information systems; d) to the vehicle lighting systems; e) to the protection of the occupants of the vehicle, which includes interior fittings, head restraints, seat belts, anchors ISOfix (ISOFIX is an international standardized system for anchoring the child's car seat). Compared to the attachment with the ISOFIX safety belts it is safer, easier and faster as it involves the attachment of the seat directly to the car seat or child restraints already fitted as standard and part of the vehicle; f) to the external part of the vehicle and to the accessories; g) to electromagnetic compatibility; h) acoustic signaling devices; i) heating systems; j) protection devices against unauthorized use; k) vehicle identification systems; l) to the masses and dimensions; m) electrical safety; n) to gear shift indicators.

Regulation 661/2009 / EC establishes that all vehicles of category M1 are equipped with precise tire pressure monitoring systems capable of issuing, where necessary, a warning inside the vehicle for the driver in the event of a loss of pressure in one of the tires, in the interest of optimum fuel consumption and road safety. To achieve this, appropriate limits are set in the technical specifications, which also allow an approach based on technological neutrality and cost efficiency for the development of precise tire pressure monitoring systems. For M1 vehicles, the reference mass of which does not exceed 2610 kg and the M2, N1, N2 vehicles whose reference mass does not exceed 2840 kg, if fitted with manual transmission, are equipped with gear shift indicators in accordance with the requirements of Regulation 661/2009 / EC and related implementing measures (detailed rules on procedures , tests and specific technical requirements for the approval of motor vehicles, their trailers, components and separate technical units). Vehicles belonging to categories M1 and N1are equipped with an electronic stability control system that complies with the requirements of the same regulation and related implementing measures (safeguarding the safety of occupants of motor vehicles and surrounding individuals). Except for off-road vehicles (4°), the following vehicles belonging to the categories listed below are equipped with an electronic stability control system which meets the requirements of Regulation 661/2009 / EC and its implementing measures: (a) vehicles belonging to categories M2 and M3 excluding those with more than three axles, buses, articulated buses and class I or class A buses; (b) vehicles belonging to categories N2 and N3, excluding those with more than three axles, tractors for semi-trailers with a gross mass of between 3,5 and 7,5 tonnes and special purpose vehicles as defined in items 5.7 and 5.8 of Part A of Annex II of Directive 2007/46 / EC; c) vehicles belonging to categories O3 and O4 equipped with air suspension, excluding those with more than three axles, trailers for exceptional transports and trailers which have spaces intended for standing passengers.

(4°) NOTE: Criteria for sub-classification of vehicles as off-road vehicles. Vehicles M1 or N1 must be sub-classified as off-road vehicles if they meet all the requirements to follow: a) at least one front axle and one rear axle are designed to be simultaneously engines, regardless of the possibility; to disengage the motricity of an axis; b) are equipped with at least one differential locking mechanism or a mechanism having a similar effect; c) they can travel a slope of at least 25% without a trailer; d) satisfy five of the six requirements to follow: i) have an angle of attack of at least 25 degrees; ii) have an exit angle of at least 20 degrees; iii) have a ramp angle of at least 20 degrees; iv) have a ground clearance below the front axle of at least 180 mm; v) have a ground clearance below the rear axle of at least 180 mm; (vi) have a height above ground between the axles of at least 200 mm. Vehicles of categories M2, N2 or M3 whose maximum mass does not exceed 12 tonnes shall be sub-classified as off-road vehicles, if they satisfy the requirement referred to in point (a) or both of the requirements referred to in points (b) and (c): (a) all their axles are simultaneously engines, irrespective of the possibility to disengage the motricity of one or more axes; (b) (i) at least one front axle and one rear axle are designed to be simultaneously engines, irrespective of the possibility to disengage the motricity of an axis; ii) are equipped with at least one differential locking mechanism or a mechanism having the same effect; iii) can travel a 25% incline without a trailer; c) satisfy at least five of the following six requirements, if their maximum mass does not exceed 7.5 tonnes, and at least four, if their maximum mass exceeds 7.5 tonnes: (i) have an angle of attack of at least 25 degrees; ii) have an exit angle of at least 25 degrees; iii) have a ramp angle of at least 25 degrees; iv) have a ground clearance below the front axle of at least 250 mm; v) have a height free from the ground between the axles of at least 300 mm; (vi) have a ground clearance below the rear axle of at least 250 mm. 4.3. Vehicles of categories M3 or N3 whose maximum mass exceeds 12 tonnes shall be sub-classified as off-road vehicles if they meet the requirement referred to in point (a) or both the requirements referred to in points (b) and (c): (a) all their axles are simultaneously movable, regardless of the possibility; to disengage the motricity of one or more axes; b) i) at least half of the axes (or two axes out of three in the case of a three-axle vehicle and mutatis mutandis in the case of a five-axle vehicle) are designed to be simultaneously engines, irrespective of the possibility; to disengage the motricity of an axis; (ii) are equipped with at least one differential locking mechanism or a mechanism having a similar effect; iii) can travel a 25% incline without a trailer; c) satisfy at least four of the six requirements to follow: i) have an angle of attack of at least 25 degrees; ii) have an exit angle of at least 25 degrees; iii) have a ramp angle of at least 25 degrees; iv) have a ground clearance below the front axle of at least 250 mm; v) have a height free from the ground between the axles of at least 300 mm; (vi) have a ground clearance below the rear axle of at least 250 mm.

This Regulation (661/2009 / EC) shall enter into force on the twentieth day following that of its publication in the Official Journal of the European Union. It shall be applicable from 1 November 2011 and shall be binding in its entirety and directly applicable in all Member States.

In consideration of the rules for the implementation of Directive 661/2009 / EC, the European Commission adopts Regulation 65/2012 / EU. With reference to the definition of manual gear shift (or automatic gear shift with manual gearshift function) reported above, the GSI system is defined. A gear shift indicator that signals to the driver when it is appropriate to gear shift, reduce or increase, to minimize fuel consumption; the automatic transmission adopts the system to reduce consumption automatically. An important factor for ecological driving is proceed in the correct gear and change at the right time. GSI (Gear Shift Indicator) - which signals when it is appropriate to gear shift up or down to minimize fuel consumption. To optimize performance, prevent vibrations or other reasons, you can however, it is advisable to change gear at a higher speed. With the regulation 65/2012 / UE the European Commission defines the characteristics of the GSI system below: 1) the recommendation to change gear should be transmitted with a separate optical indication, as a signal that clearly invites to go from a gear shift higher or lower or a symbol which identifies the gear in which the driver should change. The optical indication can be supplemented by other indications, including sound, provided they do not compromise security. 2) The GSI must not make it difficult or prevent the identification of warning lights, controls or indicators that are prescribed or induce the safe operation of the vehicle. The signal must be designed in such a way as not to distract the driver's attention and not to interfere with the correct and safe operation of the vehicle in compliance with the following characteristics. 3) The GSI must be placed in compliance with in the paragraph 5.1.2 of UN / ECE regulation no. 121 (Warning lights and indicators must be placed visibly and recognizable by drivers - both at night and during the day - in conditions where the driver must have adapted to the light conditions of the environment and must be considered by the impact protection system , adjusted according to the manufacturer's instructions, and be free to move within the limits set by this system). Is not necessary that spies and indicators are visible or recognizable if they are not activated. It should be designed so that it is not confused with other lights, controls or indicators that equip the vehicle. 4) To show the indications of the GSI you can use an information display device they must differentiate themselves sufficiently from other signals and be clearly visible and identifiable by the driver. 5) In exceptional situations, the indications of the GSI can be temporarily canceled or deactivated automatically. These are situations that could compromise safe operation or integrity of the vehicle relating to the activation of traction control systems or stability, to the temporary display of driver assistance systems or to warnings relating to the vehicle malfunctioning. The GSI must be able to return to normal operation within 10 seconds, as soon as the exceptional situation ceases or within a greater period of time if it occurs is justified by technical or behavioral reasons.

Functional requirements. The GSI invites to change gear as soon as it estimates that with the recommended gear shift the fuel consumption would be less than consumption with the gear at that time inserted, taking into account the following requirements: the GSI must be designed to encourage an optimized driving style , aimed at saving fuel in reasonably predictable driving conditions. Its main purpose is to minimize the fuel consumption of the vehicle when the driver follows his directions. Following the indications of the GSI, the regulated emissions that escape from the exhaust must not however increase disproportionately with respect to the initial state. Furthermore, if the GSI strategy is adopted (to reduce harmful emissions), this must not compromise the timely functioning of the pollution control devices (catalyst) after a cold start. To this end, vehicle manufacturers will provide the type approval authority with technical documents describing the impact of the GSI strategy on regulated emissions escaping from the exhaust, at least under constant speed conditions. Applying the GSI designation must not compromise the proper functioning of the vehicle and cause engine stoppage, insufficient engine braking or insufficient torque at the time of strong power demand.

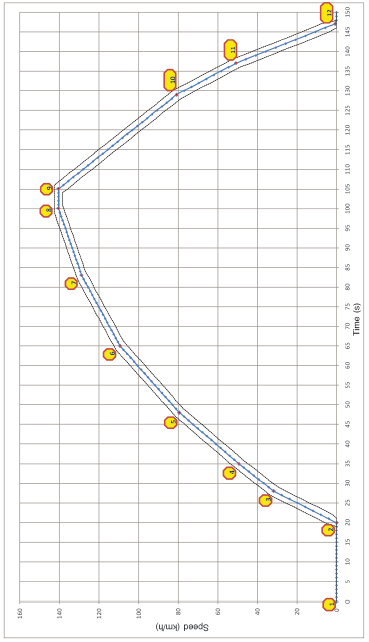

The manufacturer must provide the documentation relating to the tests carried out to determine the impact on fuel economy of the gear change points recommended by the GSI. This test must be carried out on a hot vehicle and on a dynamometer with roller, according to the speed profiles in the figure below. The invitation of the GSI to move to a higher gear will be followed and the vehicle speeds to which the GSI recommends to change are recorded. The test is repeated 3 times. The definition of the gear change speed (from a lower gear to a higher gear) is defined in consideration of the speed profiles in the figure below, with reference to the acceleration that must fall within the margins defined in the same figure for each gear engaged. Alternatively, the exchange gear speed recommended by the GSI can be calculated by the manufacturer analytically based on the GSI algorithm contained in the complete documentation file, presented with the application for approval to the authority of the Member State, reported below: the manufacturer must provide the type-approval authority with the following information. The information must be made available in the following 2 parts: a) the formal documentation, which, upon request, can be given to interested parties; b) the expanded documentation , which remains strictly confidential. The formal documentation must contain: a) a complete description of all the aspects that can be assumed by GSIs that are mounted on vehicles belonging to the vehicle type, in relation to the GSI, and a certificate that they meet the characteristics of the GSI system (above ). (b) attested, in the form of data or technical expertise - such as data on modeling, emission or consumption maps, emission tests - demonstrating adequately that the GSI recommends to the driver, in an effective and timely manner, appropriate gear changes, suitable to satisfy the functional characteristics (indicated above). c) an explanation of the purposes, use and functions of the GSI in a GSI section of the user manual that accompanies the vehicle.

Graphical representation of the vehicle speed profile; continuous line: speed profile; discontinuous lines: deviation tolerated by this velocity profile.

Regulation 65/2012 / EU shall enter into force on the twentieth day following that of its publication in the Official Journal of the European Union. The regulation is binding in its entirety and directly applicable in all Member States.

4 - EMISSION LIMITS HARMFUL SUBSTANCES FOR INTERNAL COMBUSTION ENGINES. The European Parliament and the Council of the European Commission with regulation 595/2009 / EC amends directive 2007/46 (annexes) and fixes the EURO VI harmful emissions limits for internal combustion engines. The internal market comprises an area without internal frontiers in which the free movement of goods, persons, services and capital must be ensured. To this end, a general Community type-approval system applies to motor vehicles. The technical requirements for the approval of motor vehicles with regard to emissions should therefore be harmonized in order to avoid the adoption of different requirements from one Member State to another and to ensure a high degree of environmental protection. In order to improve air quality and to meet pollution limit values and national maximum emission levels, it is in particular necessary to reduce the NOxemissions of heavy vehicles. Setting the limit values for NOx emissions at an early stage should give motor vehicle manufacturers long-term planning certainty on a European scale. When setting emission standards it is important to consider the implications for the competitiveness of markets and builders, the direct and indirect costs for businesses, the increasing benefits in terms of stimulating innovation, improving air quality, reducing healthcare costs and increasing people's safety by reducing the proportion of indirect causable injuries. In order to improve the functioning of the internal market, in particular as regards the free movement of goods, freedom of establishment and freedom to provide services, unlimited access to vehicle repair information is required, through a standardized search function which allows to obtain technical information, and effective competition on the market for information services relating to vehicle repair and maintenance. Much of this information refers to OBD (5°) onboard diagnostics and their interaction with other vehicle systems. It is necessary to establish the technical characteristics which manufacturers must comply with when providing information on their websites, as well as the targeted measures ensuring reasonable access to small and medium-sized enterprises.

(5°) NOTE: on-board diagnostics, from English on-board diagnostics, OBD or OBD-II, in a car, motorbike or motor vehicle context in general, is a generic term referring to the ability to self-diagnose and report errors, faults in a vehicle. Before the self-diagnosis, it was the mechanics who had to diagnose the faults, while now it is the on-board ECU that self-checks and checks the status of the vehicle. OBD systems provide the vehicle owner or mechanic access to information on the "health status" of the various vehicle subsystems: standard legislation (in Europe and the United States) refers only to the "emission relevant" subsystems, ie those which, if broken, they can lead to an increase in emissions, such as catalytic converter, lambda probe, etc., while the other systems (eg airbag, air conditioning, etc.) have a non-standard self-diagnosis, defined at will by each car manufacturer. The amount of diagnostic information available via OBD has changed a lot since the introduction in the early 1980s of on-board computers in motor vehicles (control units) that made OBD possible. The first implementations of OBD simply switched on a warning light in the case of problems, but did not provide any further information regarding the nature of the problem. Modern OBD implementations use a digital communication port to provide real-time information in addition to an alert to the nature of the problems by means of standard diagnostic code (DTC) "Diagnostic Trouble Codes" which allow to quickly identify and solve vehicle malfunctions. The OBD-II is a standard defined in the United States in the mid-nineties that allows complete control over engine parameters and monitoring other parts of a vehicle such as the chassis and accessories; it also allows you to connect to the diagnostic system. OBD-II was issued by the California Air Resources Board. The OBD-II is primarily a read-only interface for acquiring diagnostic signals. The OBD-II standard also defines some commands for controlling the output, for self-checking modes and for resetting the KAM (Keep Alive Memory) memory. Even the control units of the motorbikes, even if they do not have the obligation, sometimes have the OBD protocol, since they often derive from those of the cars. US vehicle manufacturers were required to convert diagnostic connections to the OBD-II standard in 1996; until 1994 many houses used proprietary connections. Where there is no legal requirement for the detection of pollution-related parameters (eg for gasoline engines before 2001), instead of OBD-II it is called OBD-I, ie a diagnosis on board related to electrical errors. Starting in 2000, the European community, together with the stringent emission limits established by the Euro3 legislation, has adopted the EOBD standard that derives from OBDII, making it mandatory for all new vehicles. As a consequence, all car manufacturers have had to adapt, both as regards the fault codes, and for the real self-diagnosis interface, starting from the communication protocols up to the 16-pole connector for the tester connection. It applies to all M1 category cars (with no more than 8 seats and a gross vehicle weight of up to 2500 kg) registered for the first time in EU Member States from 1 January 2001 for cars with petrol engines and from 1 January 2004 for diesel-powered cars. For newly introduced models, the dates of application of the legislation were brought forward by one year: 1 January 2000 for petrol cars and 1 January 2003 for diesel cars. For passenger cars with a gross vehicle weight of more than 2500 kg and for light commercial vehicles, the dates of application of the legislation started from 1 January 2002 for petrol models, and from 1 January 2007 for diesel models. The technical implementation of the EOBD is essentially the same as OBD-II, and the same SAE J1962 connection and signal protocols are used. The EOBD emission thresholds for the Euro V and Euro VI regulations are lower than the previous Euro III and IV.

Regulation 595/2009 / EC lays down common technical requirements for the approval of motor vehicles, engines and spare parts with regard to their emissions. The same regulation also establishes rules for the in-service conformity of vehicles and engines, the durability of pollution control devices, OBD systems, the measurement of fuel consumption and CO2 emissions and the accessibility of vehicle OBD information and vehicle repair and maintenance information. This Regulation applies to motor vehicles of categories M1, M2, N1 and N2, as defined in Annex II to Directive 2007/46 / EC with reference mass exceeding 2 610 kg and to all motor vehicles of categories M3 and N3, defined in the same annex.

Manufacturers must ensure compliance, within the scope of the approval, with the procedures for verifying conformity of production, durability of pollution control devices and in-service conformity. The technical measures taken by the manufacturer must ensure that the exhaust emissions are effectively limited, within the meaning of Regulation 595/2009 / EC and their implementing measures, throughout the normal life of vehicles under normal conditions of use. To this end, mileage and time periods, with respect to which the durability tests of the pollution control devices for the approval and proof of conformity of vehicles or engines in service must be carried out, are as follows: a) 160 000 km or five years, whichever comes first, for engines installed on vehicles of categories M1, N1 and M2; b) 300 000 km or six years, whichever occurs first, for engines installed on vehicles of category N2, N3 of technically permissible maximum mass not exceeding 16 tonnes, and M3 class I, class II and class A, and class B of technically permissible maximum mass not exceeding 7,5 tonnes; c) 700 000 km or seven years, whichever occurs first, for engines installed on vehicles of category N3 of technically permissible maximum mass exceeding 16 tonnes, and M2, class III and class B of technically permissible maximum mass exceeding 7,5 t. Manufacturers shall manufacture vehicles and engines in such a way that the components capable of affecting emissions are designed, constructed and installed in such a way as to allow the engine or vehicle, in normal use, to meet the EURO VI emission limits, Annex I of Directive 595/2009 / EC. The use of manipulation strategies that reduce the effectiveness of emission control systems is prohibited. The regulation shall enter into force on the twentieth day following its publication in the Official Journal of the European Union and shall be binding in its entirety and directly applicable in all Member States.

The European Commission, having regard to the regulation (EC) no. 715/2007 laying down common technical requirements for the approval of motor vehicles and spare parts with regard to their emissions and establishing compliance rules in service, on the duration of pollution control devices, on-board diagnostic (OBD), fuel consumption measurement and accessibility information for vehicle repair and maintenance. Considering the subsequent amendments made by the EC Regulation No. 692/2008 of the Commission of 18 July 2008, implementing and amending the EC Regulation number 715/2007, concerning the approval of motor vehicles with regard to emissions from light commercial and passenger vehicles ( Euro 5 and Euro 6) and to obtain information for the repair and maintenance of the vehicle, establishes the administrative provisions for the control of conformity of vehicles with regard to CO2 emissions and establishes the requirements for the measurement of CO2emissions and the fuel consumption of such vehicles. Given the regulation (EU) n. 510/2011 of the European Parliament and of the Council of 11 May 2011, which defines the emission performance levels of new light commercial vehicles as part of the integrated Union approach aimed at reducing CO2 emissions of light vehicles, establishes the obligation to establish a procedure to obtain representative values of CO2 emissions, fuel efficiency and mass of completed vehicles, ensuring at the same time that the basic vehicle manufacturer can access timely data on the mass and specific CO 2 emissions of the completed vehicle. On February 19, 2013 they adopt the regulation 143/2013 / CE concerning the determination of CO 2 emissions of the vehicles submitted for approval in more detail phases that make changes to the Annexes of Directive 2009/45 / EC. The regulation is mandatory in its entirety and directly applicable in each of the Member States.

5 - PEDESTRIAN SAFETY. In Part I of Annex IV of Directive 2007/46 / EC, "for vehicles belonging to category M1" the technical requirement is defined : the vehicles are equipped with an electronic anti-lock braking system acting on all the wheels; the technical requirement is necessary for the homologation of the prototype to which all the subsequent vehicles of category M1 of the same type of the prototype will have to be compliant for matriculation.